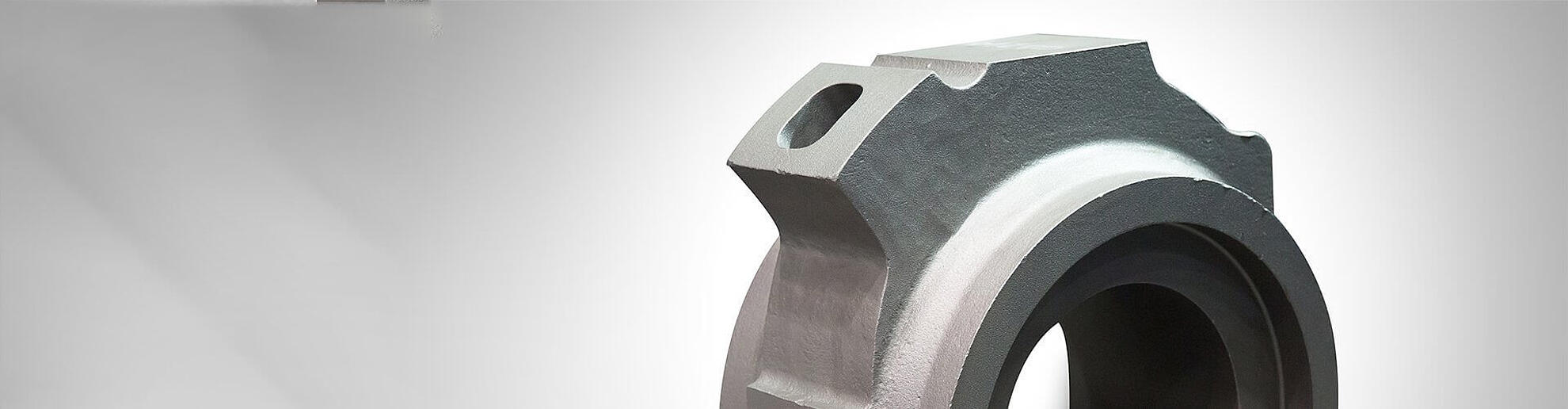

Stainless steel casting

Silbitz Group is the perfect partner when it comes to stainless steel casting. In our casting plants we produce stainless steel casting according to various methods and with a broad range of different materials.

Characteristics and application areas of stainless steel casting with flake graphite

Stainless steel casting with flake graphite is made of a casting alloy of iron, carbon and silicon, in which graphite is present in irregular formed thin flakes. On one hand it reduces the tensile strength, but on the other hand it increases the compressive strength of this material by a factor of four. Furthermore, this material provides exceptionally good damping characteristics with regard to the shape retention and the thermal conductivity. The fairly high corrosion resistance can be improved even further by alloying elements such as chromium, nickel or silicon. This stainless steel casting has a very good castability and machinability, it dampens vibration and possesses good self-lubricating properties according to suitable treatment. The drawbacks of stainless steel casting are its low formability, the low tensile strength and the brittleness. Therefore, this casting is often used for geometrically complex parts, such as crankcases, gas and steam turbine housings and pumps, valves and compressor housings.

Characteristics and application areas of stainless steel casting with spheroidal graphite

Spheroidal graphite is made of a casting alloy of iron, carbon and silicon. This material has substantially better mechanical properties than flake graphite, as the graphite interstratifications are spherical in shape. This is achieved by desulphurise the material during the melting process by adding small quantities of calcium, magnesium or cerium. Stainless steel casting with spheroidal graphite features a good castability, a high strength and toughness, as well as a good tensile strength. Stainless steel casting is often used for metallurgy, turbines, compressors, shipbuilding and mining.

Characteristics and application areas of stainless steel casting with vermicular graphite

This stainless steel casting shows a worm-like graphite form and an increased strength. In comparison to flake graphite, the stainless steel casting with vermicular graphite has a lower notch-effect. This obviously affects the castability, which is however still high enough to cast more complex forms. Stainless steel casting is generally used for cylinder heads or cylinder crankcases as well as for general mechanical engineering applications.

Characteristics and application areas of Austempered Ductile Iron (ADI)

The carbon within Austempered Ductile Iron stainless steel casting is spherical and the structural matrix consists of ausferrite. This is a fine-grained mixture of stabilized ausferrite and ferrite, which leads to a high strength and ductility. ADI stainless steel casting is used for general mechanical engineering applications.

Characteristics and application areas of Austenitic Cast Iron

Stainless steel casting of austenitic cast iron consists of flake and spheroidal graphite. Their common characteristic is an austenitic matrix. These cast types have outstanding physical and technological properties and can be used in diverse applications. This stainless steel casting is corrosion-resistant, temperature-resistant, wear-resistant, non-magnetizable and has excellent running properties.

We hope that the information provided will be helpful to you. Contact us and we will find the suitable material for you.