Drive technology

Drive technology is a technical discipline that deals in general with technical systems needed to generate motion through power transmission. This includes both the drive source, the control of the corresponding drive elements, as well as the technology that is required to provide the respective machine with energy. Thus, the general drive technology may include elements of mechatronics, electric drive technology, electropneumatics and electrohydraulics.

Drive technology for large gears

The Silbitz Group offers you extremely durable components made of cast iron, the highest quality grade for your drive technology. We can prove the high quality of our castings by X-ray or ultrasound, as well as by color penetration and magnetic particle inspection. Our products are used in particular in cable cars, oil platforms, wind turbines and tunnel boring machines and many other applications. As your reliable partner, we supply castings that can cope with high thermal and mechanical loads.

Support in the development of your castings

Our engineers will assist you constructively with the help of the electronic data exchange in the development of the components required for your project. In addition, we offer you a mold filling and silidification simulation for your castings, where you can convince yourself of the high quality of our work. Our development department is constantly working on new materials that will continue to meet ever-increasing demands placed on drive technologies in the future.

The Silbitz Group – a reliable partner at your disposal

With our years of experience and our high innovative strength, we are a reliable partner for your demanding drive technology. The expansion of renewable energieswill continue in the future and particularly the efficient use of wind and hydro power requires the use of extremely resilient materials. We will continue to ensure that your plants are equipped with components made from reliable materials, even if wind turbines get even bigger and bigger.

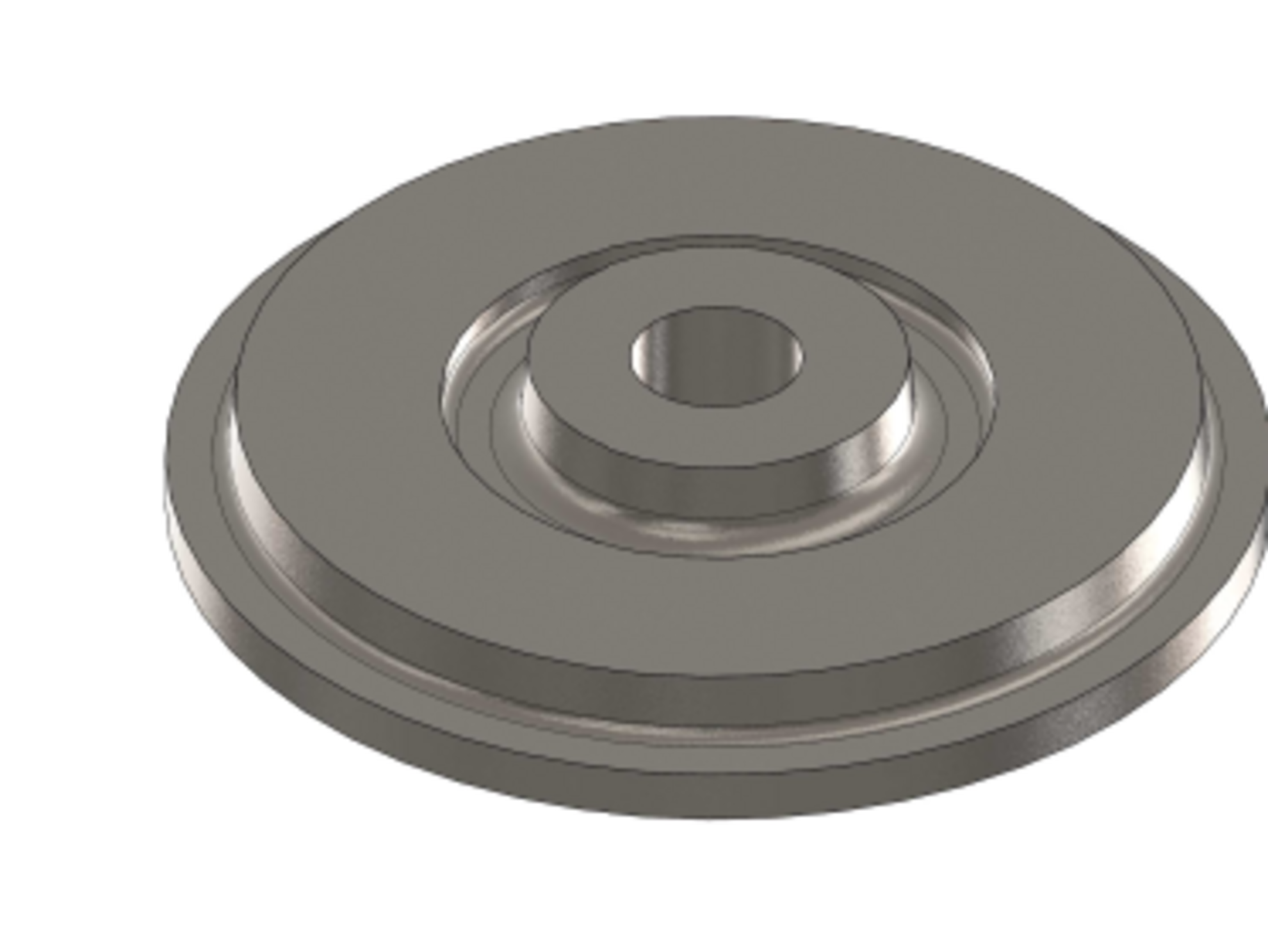

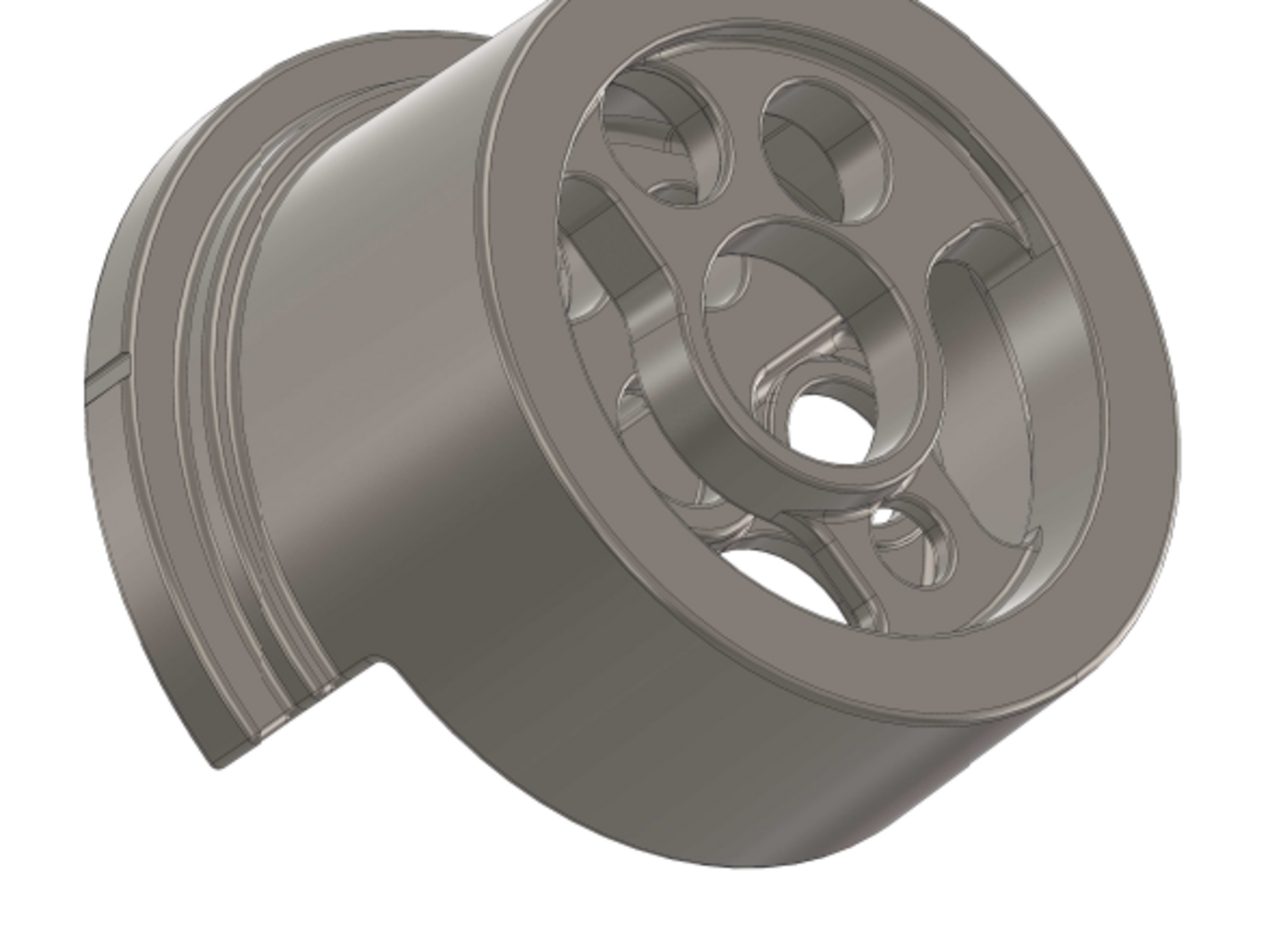

Drive technology for planetary gearboxes

Planetary gearboxes make up a large proportion of large gearboxes. We manufacture bearing housings, torque arms, flanges and covers for planetary gears made of the materials EN-GJS-400-18LT and EN-GJL as well as housings made of EN-GJL-400-15 and EN-GJL and planet carriers of EN-GJS-700-2, which is alloyed GS. All components are available in different weight classes.

Custom-fit solutions for your drive technology

The Silbitz Group is your reliable casting partner for drive components that are exposed to enormous mechanical and thermal stresses. Our engineering is in the position to advise you in the development of your components by means of pro-E-data exchange constructively and to support you at any time. Just contact us and present us your project, so that we can find the best solution together.

We are looking forward to a good cooperation.