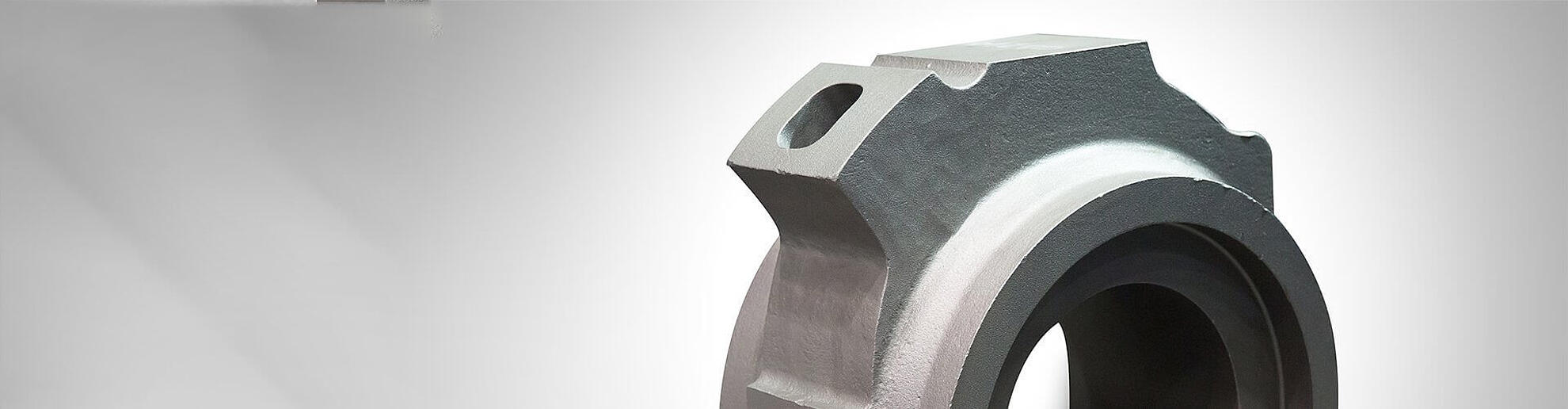

Iron casting

Iron casting in its diverse appearances

Iron casting (i.e. iron in the form of cast iron) is the central metal of the industrial revolution, which has been shown up during the last few centuries. Iron can not only be alloyed with almost every metal, but preferably even with carbon. The percentage of carbon affects the characteristics fundamentally. This entails the melting and casting characteristics, the tensile strength, the forgeability and the breaking resistance and toughness. Only a precisely known carbon content makes iron casting one of the most versatile and important metals of our time.

Differentiation between steel and iron casting

- Iron with a carbon level of 2 – 3,8 % is very suitable for producing iron castings and has the denomination iron casting

- Iron with a carbon level below 2% has the denomination steel and, according to its high tensile strength, is very suitable for producing rolled sections, metal sheets, tools and machine components made of cast steel and steel casting that has to be mechanically processed

- Iron in its pure form is soft, brittle and difficult to process and to cast. So it is basically almost unsuitable for use in a practical way, except for the production of magnets. For this purpose, it has proved itself to be particularly effective.

Special characteristics of iron casting

Cast iron, initially known as grey cast iron (EN-GJL), was with regard to the efficient casting properties, including the subsequent processing, far superior to the properties of steel. The aim of the research was therefore, to reconcile this factor with the benefits of steel. With the help of various alloys, carbon levels, heat treatments and treatments with silicon, results could be obtained that, despite the high carbon level, surpass the tensile strength and further benefits of steel.

Especially the conversion of the graphite fins into spheroidal graphite through adding silicon, introduced a revolutionary breakthrough in iron casting. This spheroidal graphite iron casting (EN-GJS) is characterized by a high tensile strength, elasticity and thermal stability.

Production and handling processes for iron casting

The Silbitz Group is producing iron casting in high modern induction furnaces with subsequent heat treatment in ember furnaces. This makes it possible to bring about structural changes by different procedures, which allows a numerous production with different qualities. This also includes iron casting that is suitable for forging, hardening or tempering. For all quenching and tempering procedures, there are water and oil tanks as well as air-cooling chambers available that are equipped with ventilators. The unit weight of an iron casting part is between 10 kilos and 45 tons.

Application areas and products

Thanks to special alloys and further heat treatments, iron casting can be used for example in the entire area of the automotive and mechanical engineering business. From heavy marine engine cases to connection rods for automobile engines, there is the adequate type of iron casting for every purpose. All iron casting qualities are classified and standardized according to DIN EN. This also includes the so called grey cast iron, which still turns out to be ideal for heavy machine tool bases as well as for pumps and engine cases. Other qualities can be used for high quality crankshafts or highly stressed machine components. This applies, for example, for the hand gear system of tailboards of modern passenger airplanes and for axle parts of vehicles.

Another specialty of the Silbitz Group is iron casting according to customer specifications in regard to individual characteristics.