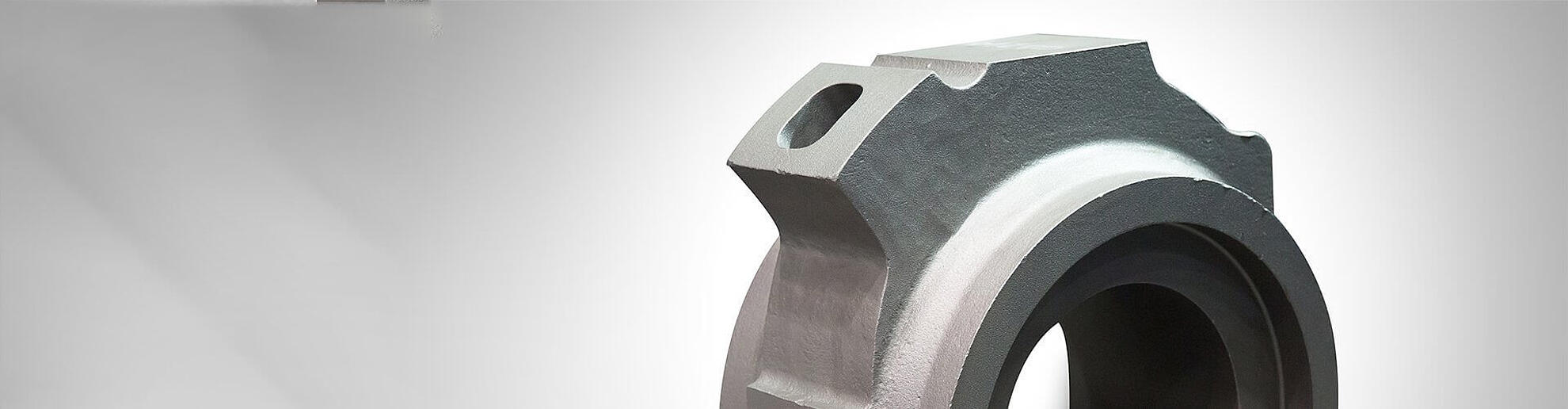

Gray cast iron - particularly robust and yet lightweight

The Silbitz Group produces cast iron, including gray cast iron and alloyed cast iron in the highest quality grades, especially for highly stressed components. In gray cast iron, the alloy consists of iron with at least 2% carbon. Due to additional alloy components such as silicon, the lamellar and spheroidal graphite formation can lead to the suppression of vibrations in special mechanical shapes, such as vibration-damping properties. Cast iron and cast steel can be produced very efficiently for a wide range of part shapes, weights and sizes. With a subsequent heat treatment of alloyed gray cast iron, we achieve further specially desired properties. Subsequent machining then reduces the initial raw weight and results in a high degree of adaptability to the desired shape.

Our services

- Cast iron with lamellar graphite (GJL, gray cast iron, grey cast iron)

- Cast iron with nodular graphite (GJS, ductile cast iron, ductile cast iron)

- Cast iron with vermicular graphite (GJV)

- Special cast iron: Ausferritic (ADI) and austenitic cast iron (NiResist)

All of the aforementioned gray cast iron variants are specified by the customer and require a high level of manufacturing quality. The Silbitz Group therefore relies on in-process testing and final inspection during and after the production of gray cast iron. Our focus is always on guaranteeing flawless product quality. The finest cavities and cracks in the matrix can lead to the rejection of cast parts, especially in gray cast iron with complex component geometries. We at the Silbitz Group therefore attach great importance to quality and safety.

Areas of application and advantages of gray cast iron

Cast iron can be used in an unlimited number of industrial applications thanks to the wide range of alloys and finishing processes mentioned above. Common areas of application for gray cast iron are commercial vehicle and railroad technology, mechanical engineering and the pump industry. Despite the highest mechanical loads, the requirement for cast iron is the lowest possible weight. At the Silbitz Group, we achieve a reduction in the gross weight by post-processing the gray cast iron.

Expertise of the Silbitz Group

The Silbitz Group manufactures castings from iron, steel and grey cast iron at three locations in a weight range from 10 kilograms to 450 tons. In Silbitz, Košice and Zeitz, the customer's part specifications can be implemented in a wide range of dimensions in the manual hand-moulding shop as well as in the mechanical hand-moulding shop and the automatic moulding plant. This enables us to fulfill a wide range of customer requirements. This makes us a partner for a wide range of industries.

With the Silbitz Group, you have an industrial partner for gray cast iron at your side. From design consulting, simulation, model making, integrated production of gray cast iron in a wide variety of alloys to sophisticated quality testing methods and logistics, we take care of your needs. Please do not hesitate to contact us!