Cast iron at the Silbitz Group

The Silbitz Group is able to manufacture cast iron and alloyed cast iron. The term "cast iron" refers to the original alloy of iron with a high content of at least 2% carbon and other alloying constituents, in particular silicon.

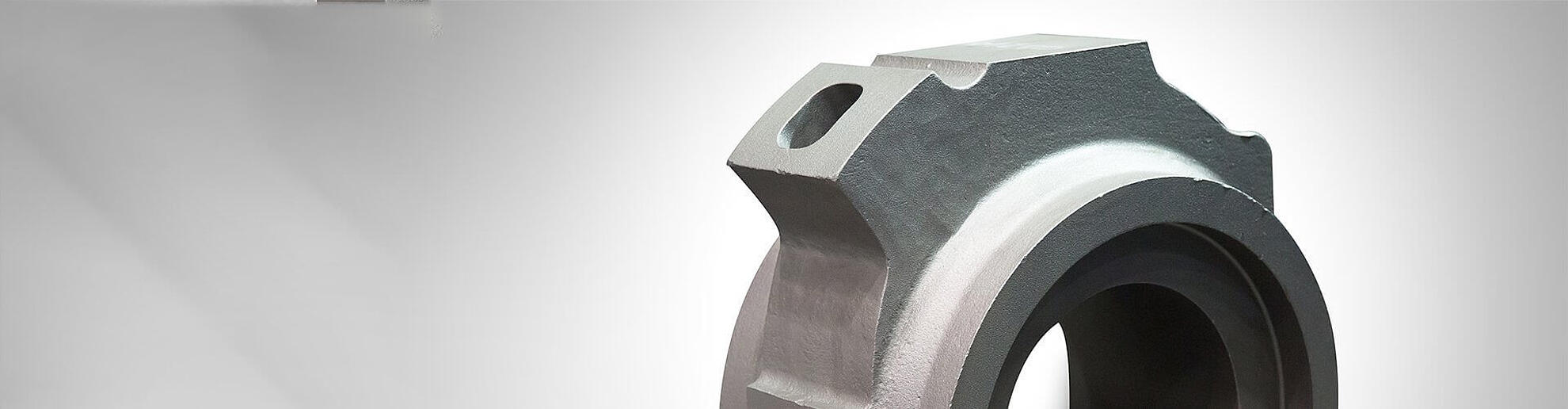

Basically, a difference is made between cast iron with lamellar graphite (GJL, grey cast iron, grey iron), spheroidal graphite cast iron (GJS, spheroidal graphite iron, ductile cast iron) and cast iron with vermicular graphite (GJV). It is also possible to produce special cast iron such as ausferritic ductile iron (ADI) and austenitic cast iron (NiResist). The various varieties are obtained by the addition of certain additional alloying elements and, if appropriate, subsequent heat treatment Further modifications regarding the properties of the respective materials of the castings can be adapted and enhanced in collaboration with the customer. Due to its vibration dampening property, cast iron is in demand everywhere where the transmission of vibrations needs to be prevented. Good examples of this are tooling machines, which have always used cast iron for machine bodies and housings.

Application of castings and their advantages

The irreplaceable advantage of cast iron and cast steel lies in the uniquely efficient and unrestricted production of parts of any shape, size and quantity. As a result, in addition to weight and material savings, considerable reductions are achieved in post-production machining. As iron can be cast in a variety of different alloys, the application areas are correspondingly unlimited. Castings are used from vehicle manufacturing to mechanical engineering of all kinds, to aircraft construction. The applications range from parts in chassis, which have to be as light as possible despite their high loads, to the several tons of heavy machinery and engine blocks, up to simple wear parts.