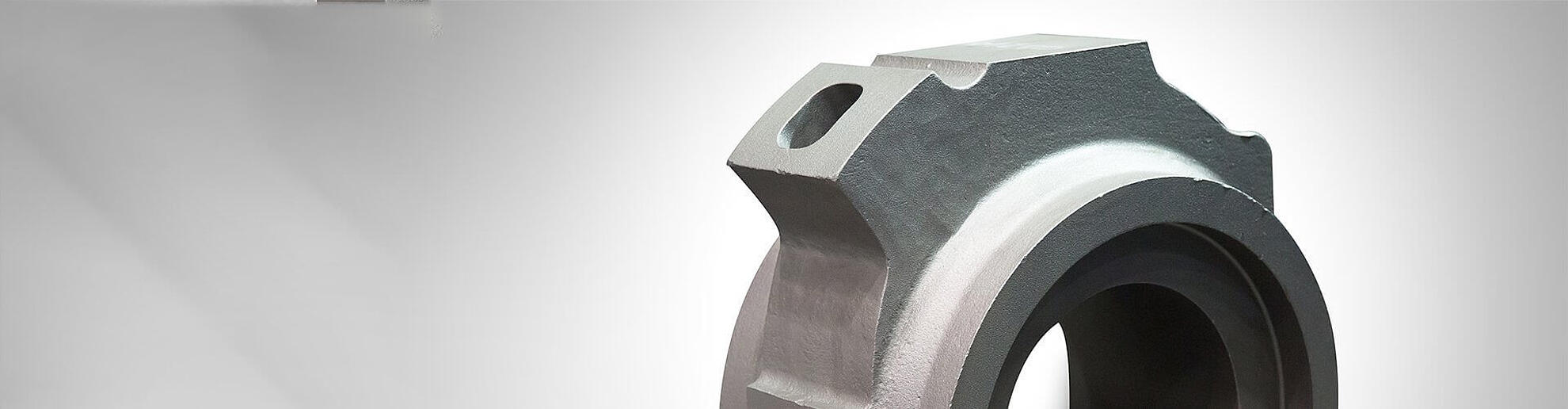

Cast materials

What are cast materials?

Cast materials are materials that have been developed and standardized especially for the casting of industrial applications. Other designations are, for example, alloys or cast alloys. Materials classified as cast alloys are also designated self-explanatory according to their specific names, for example as aluminium casting alloy or as copper alloy. An exception are the so called cast iron materials. In addition to the cast iron materials, non-ferrous alloys, steel alloys, malleable materials and wrought alloys are used. The Silbitz Group manufactures a wide range of cast iron and steel castings in its different locations and uses the cast materials for a shaping manufacturing process, the so called moulded cast. Here, the cast parts are formed in a chemical self-hardening or bentonite bonded moulding material by means of a model, consisting of a model and core boxes. The customer-specific castings are created by casting the liquid cast materials into a mould (sand mould) and letting it solidify.

Iron and cast materials

The cast materials of the Silbitz Group are grouped into two different types. We have cast steel materials on the one hand and cast iron materials on the other. The differentiation of the materials is based on the chemical composition and the resulting heat treatment process and mechanical properties. A material with a carbon content of less than 2.06% is called a cast steel material. The proportion of alloy elements is generally higher than that of cast iron materials. The cast iron materials have a carbon content of more than 2.06%. The cast materials are used in practice for a variety of applications and can be cast in different forming processes and different quantities. The cast materials (iron and steel) can be manufactured according to their application in different material grades and variants.

Special cast materials

Cast iron with lamellar graphite

Cast iron with lamellar graphite is a standardized DIN material. It has a lamellar graphite structure and may have a ferritic and / or pearkitic matrix. The chemical compositions depend on the specific conditions of use of the casting. The castings are usually characterized by a high compressive strength, good castability and relatively high vibration damping. This cast material is e.g. used in mechanical engineering.

Cast iron with spheroidal graphite

Cast iron with spheroidal graphite is a standardized DIN material. Also in this case, other material designations are used, e.g. spheroidal cast iron. When producing cast iron with spheroidal graphite, a special chemical composition is used. The process-related melt treatment with magnesium as treatment element is responsible for the spheroidal graphite formation within the cast iron. The castings are characterized in particular by higher mechanical properties, e.g. tensile strength, yield strength and elongation at break. Products that are made of cast iron with spheroidal graphite are used in the automobile manufacturing, energy technology and engine manufacturing.

White and black malleable cast iron

In practice, two types of malleable cast iron may be distinguished: white malleable cast iron (decarburized annealed malleable cast iron) and black malleable cast iron (non-decarburized annealed malleable iron). These cast materials require special smelting units and heat treatment procedures tailored to the manufacturing process. The Silbitz Group does not have these special cast materials in the production portfolio.

Cast steel

Cast steel offers a very wide range of different cast materials, which are selected and casted according to specific applications. The actual casting process is followed by a heat treatment process that is tailored to the chemical composition, in order to show the special mechanical properties. The cast steel materials are usually weldable. The Silbitz Group carries out special welding process tests for a wide variety of cast materials to meet the qualitative requirements of the welding process. The cast steel castings cover a wide range of applications of parts, which are made for the energy technology, shipbuilding, vehicle construction and special applications.

Covering a wide range of properties in the application of cast materials

Cast materials are used in particular in the industry because of their interesting mechanical properties. A decisive advantage of the forming process „casting“ is the ability to cast certain geometries close to the final dimensions. This results in constructional freedom of design when it comes to dimensioning the cast parts and optimizing mechanical processing. Due to the different cast materials with differentiated mechanical properties, there are many possibilities in the optimization of component dimensions and wall thickness. The possibilities of weight reduction by using cast materials of higher quality is incumbent on the designer of the cast parts. The component design is optimized through the use of constructive simulation techniques and the selection of suitable cast materials, in order to meet the customer-specific requirements.

The Silbitz Group is your adequate contact regarding design consulting, the casting-related model construction of the cast parts and the selection of suitable cast materials.