Remelting

Remelting: definition and application areas

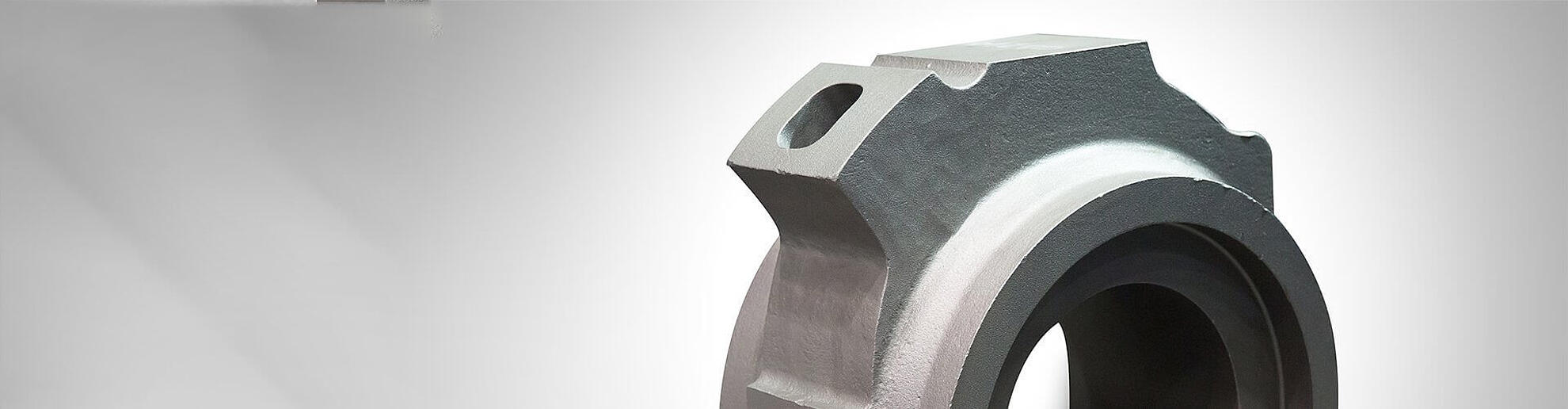

Remelting is the signification for a shape modification of deformable material, parts and components through heat, in order to re-introduce them into the business circle after this process. Defective and worn components that are no longer required can become a completely new, practical and usable quality product through the remelting process. Remelting means to modify metal through heat and not only to melt it down but to give it a new shape and hence a new application area.

Remelting of return material for re-use

In the companies a lot of scrap metal is produced through the abrasion of metal and the ordinary course when it comes to the durability of components. Every defective part has to be renewed whereby the raw material needs metal and has to be reshaped. Instead of dispose of the metal parts and to transport them to the scrap yard, remelting is a modern, practical and cost-saving method. Anyone deciding to remelt the metal and to give it a “new life”, acts environmentally friendly and can increase the efficiency within the company. The remelting process is an important remit of the value chain and makes it possible to reuse the metal of defective parts and components that are no longer required and to use them again.

Well advised from the simulation to the quality inspection

A professional remelting process requires long-term experience, expertise, adequate facilities and a sufficient heat generation. When metal is brought into a new form, all residues and components that are not needed anymore will be removed in advance. The simulation and calculation of the effort and, if required, a manual dismantling according to the highest quality requirements are part of the services offered by the Silbitz Group.

A well-founded consultancy in advance, based on long lasting experience and an excellent know-how, shows all options you have when remelting components no longer required and indicates, what costs can be expected and what savings can be gained. Not only the material, which will be remelted, but also new product are subject to continuous quality inspections.

The advantage of remelt: less waste, higher efficiency

Remelting is an economically efficient and ecological better decision and leads to the fact that material can be re-integrated into the company, thanks to its new form with high-quality characteristics and a long-lasting performance.

By using already existing material, the company saves the money it would have spent for iron or other materials and is only using its budget for the remelting process. Another advantage: The production of waste is reduced sustainably and hence a minimization of disposal costs will be achieved.