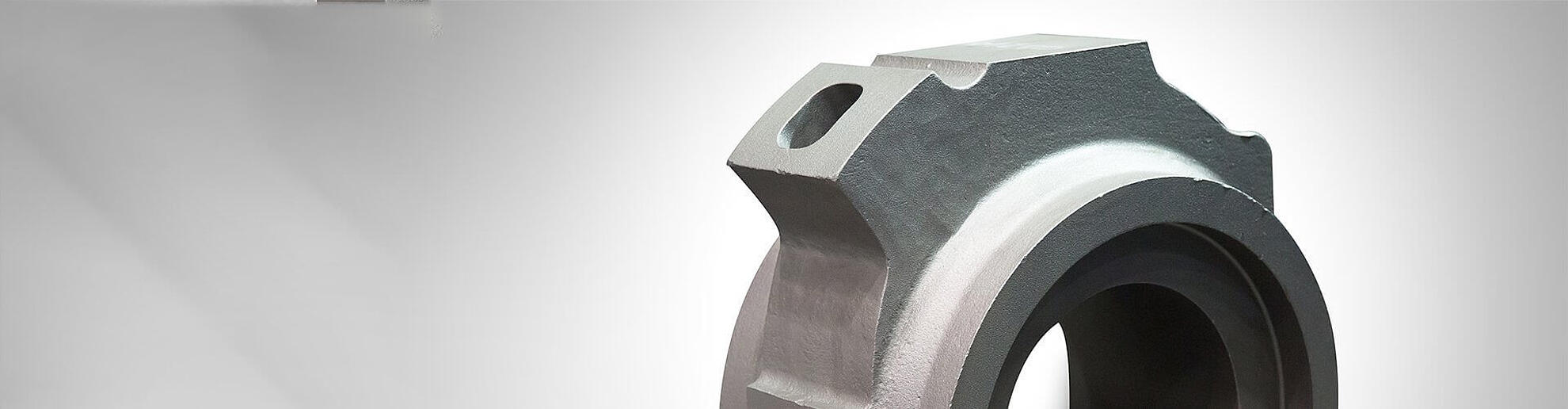

Block format

Block format in various sizes and materials

Block formats can be realized in the classic casting process or in mechanical production. There is a wide range of options between individual and standardized sizes, designs and materials. Thanks to state-of-the-art equipment and a broad portfolio of shaping options as well as different heat development, orders for a block format can be realized reliably and within a short period of time. Every manufacturing process is quality-monitored from simulation to completion. In this way, we guarantee that the ordered block format meets the highest standards and is geared to the requirements of the area of application.

Definition

The block format is a shape that can have different dimensions. As a rule, a block is a cube or cuboid with different edge lengths. The special feature of the block format is the variety of metals. The block format can be produced as a prototype or in serial production. Thanks to the modern technology and size of our systems, block formats in special sizes and with heavy weights are possible without any problems.

The casting process for the production of block formats

The simplest and quickest method for block format production is the casting process. Pattern casting is based on a mold whose internal dimensions are the correct size of the block and is used to pour in the heated liquid metal or other material. For a single block, the mold is created from a sand mixture, while the block format is produced in series in reusable molds. A clean mold with precise edges is the basis for a block format whose dimensions correspond to the order and ensure a high-quality block in precision production.

Block format in various sizes and materials

A block format can be used in various industries and areas. Depending on the material and size, it plays an important role in the construction industry, in the manufacture of machine tools and construction machinery. Blocks produced using the casting process can weigh between 300 kilograms and 9 tons, which is why they are mainly used in heavy industry and in shipbuilding or heavy-duty cranes. The Silbitz Group can determine which block format is suitable for the customer's particular application in a detailed consultation prior to simulation and calculation. Block formats in special shapes increase the range of applications and lay the foundation for a wide variety of intended uses.

Sustainable quality through quality testing in all manufacturing processes

The quality inspection does not just take place at the end, but during the production process. This reduces the error rate to zero and each production step is checked for dimensional accuracy and material quality. Once the block format has been completed, a final quality check is carried out before the product is delivered to the customer's site via the company's own logistics department.