Casting technology

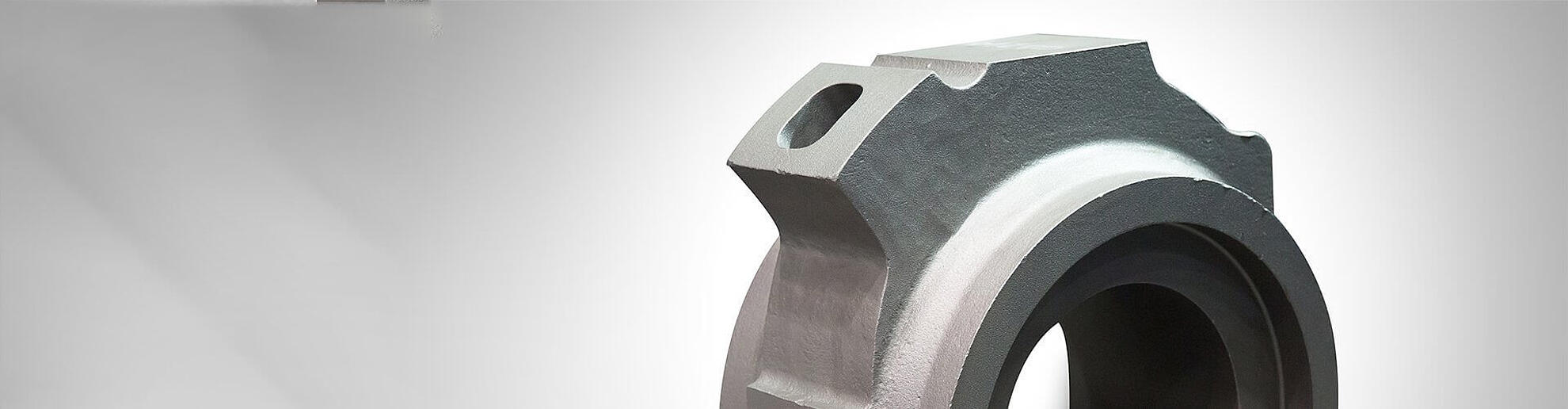

Casting technology is a forming process for the production of metallic products. It is one of the most economic measures for the production of complex geometrical component geometries of all kinds.

The forming of parts and semi-finished products occurs through melting and subsequent cooling of metal in a mold, together with the corresponding chemical composition. Various plants make different casting technologies for the relevant final products possible. Casting parts, which are produced by the Silbitz Group through casting process, can have a weight of 10 kg to 45 tons per part. The term casting technology includes numerous production methods for metallic products, which are cast into a mold and mainly completed through mechanical machining. Casting technology describes the part production, which takes place through the casting of liquefied metal through heat into an appropriate mold and which therefore belongs to the so called forming processes.

Different types of castings and casting technologies

Cast parts are produced through different casting procedures and casting technologies. We have the fully automated production process through moulding machines, as well as manual production processes, for example the hand-moulded process, with less mechanical processing steps but a subsequent mechanical and shape-cutting finishing for especially precise shapes and final dimensions. The decision for the optimum casting technology is based on the customized material and the application area of the cast parts. Through various heat treatment processes, metals of various grades and mechanical properties can be produced. For cast blocks of particularly pure metal, a remelting process through ESU-electrodes or DETEM-plant is made after the regular block casting, in order to remove or rather disperse undesired elements via their slag-bonding.

Quality control in every process of casting technology

The quality products from innovative casting technology is based on a high quality production. The process starts with the simulation of the casting technology and of the subsequent cutting as well as the solidification process of the cast part, and reaches to the design of the model concept as well as the specifications of the actual production process and the further mechanical machining. The associated logistic solutions are at the end of the process chain. By the material and product quality control, which takes place in every processing step, maximum precision and efficiency are reached. The Silbitz Group only delivers cast parts that meet the demands of quality and are in accordance with the specification, with a logistic all-inclusive solution directly to the place of destination. Here again the quality control plays a superordinate role. With the help of a casting simulation carried out in advance, technological parameters are determined according to the customized casting technology.

Casting technology and process by the specialist

The Silbitz Group is working in different segments of casting technology and has extensive expertise based on many years of casting technology experience. All products comply with the quality parameter “made in Germany” and are produced according to the latest quality criteria of the European and international standards and norms. Large and small series for various sectors and diverse products for components of steel or iron can be produced in high quality through one of the casting technology procedures. Even the production of single parts as well as the realization of complex orders are possible in various versions, thanks to the most modern casting technologies and powerful machine support.