Cylinder head

Application areas for cylinder heads

The cylinder head is one of the most important components of the engine. The Silbitz Group manufactures cylinder heads for ship engines and railway applications. Further fields of application for cylinder heads of high-quality cast materials are engines for securing long-term energy supply, which are necessary in the industrial application for generating energy. The cylinder heads are in use in stationary and mobile engines. For further information, please don’t hesitate to contact us.

Cylinder head – an important element of a combustion engine

The cylinder head, as an important element of a combustion engine, is made of cast iron material. The cylinder head closes the combustion chamber of the engine at the top. The signification „top“ is to be understood from the point of view of the oscillating piston. We are also talking about cylinder heads when it comes to boxer engines and engines, which are installed in a suspended position (aircraft engines), even though they aren’t positioned on top spatially.

The cylinder head harbours the following components in the following engine types:

- Intake and exhaust ducts, valve control for the gas exchange process, oilways for the oiling of the valve train: in all modern four stroke engines

- Coolant channels: in water-cooled engines

- Spark plugs: in gasoline engines

- Injection valves: in direct-injection gasoline engines

- Injection nozzles and heater plugs: in diesel engines

Due to the complicated production process, the cylinder head is among the most complicated and most expensive components of an engine.

Characteristics of a cylinder head

The cylinder head is manufactured according to the function of the related engine. That means that it is especially constructed, dimensioned and produced for one special type of engine. The construction of the cylinder head depends on the fact, if it is a two-stroke or a four-stroke engine. The construction of a cylinder head for a two-stroke engine is much easier. A four-stroke engine requires different flow channels for the inlet and outlet of the gas mixture. Furthermore, oil channels are integrated, which ensure the permanent supply of lubricant to the engine. In water-cooled engines, cooling channels are integrated in the cylinder heads.

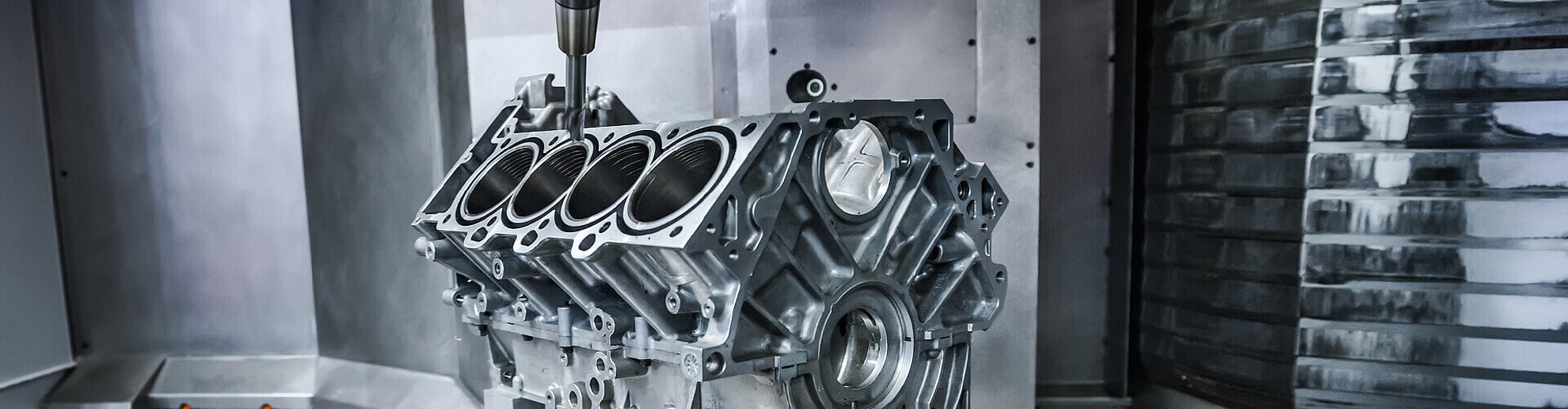

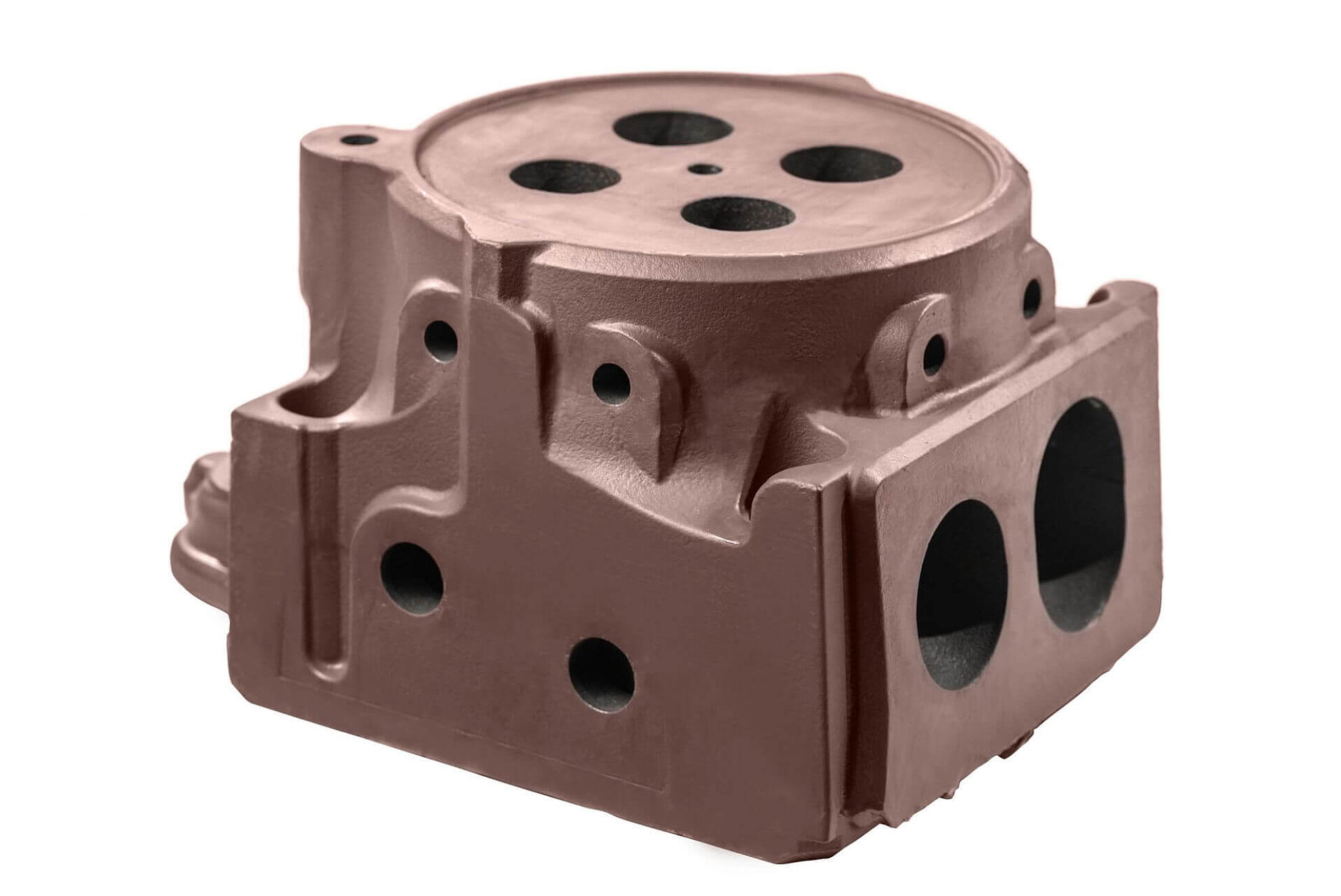

Production of a cylinder head

Cylinder heads are cast from high-quality cast iron materials. During the operation of the engines, extremely high forces are acting on the cylinder head. Due to this it is necessary that the cast iron material meets the required mechanical properties and that it is temperature change resistant. The dimensions and the structure of the cylinder head are based on the constructive requirements of the engine. The production of a cylinder head in a foundry poses a particular challenge to the caster. The construction and the design of the individual cores, as well as the assembling of the cores made of quartz-bound moulding materials form the basic framework of the actual form. The cores form the interior of the cylinder head, for example cooling and lubrication channels. Using 3D milling technology and special simulation software for the solidification processes, the risk of production-related errors are minimized. After the casting process, the cylinder head is subject to a cleaning, grinding, blasting and a mechanical machining process. The resulting cylinder head is in a ready-to-install state after mechanical processing and the prescribed pressure test.