Cylinder housings

Cylinder housings - versatile use in various sectors

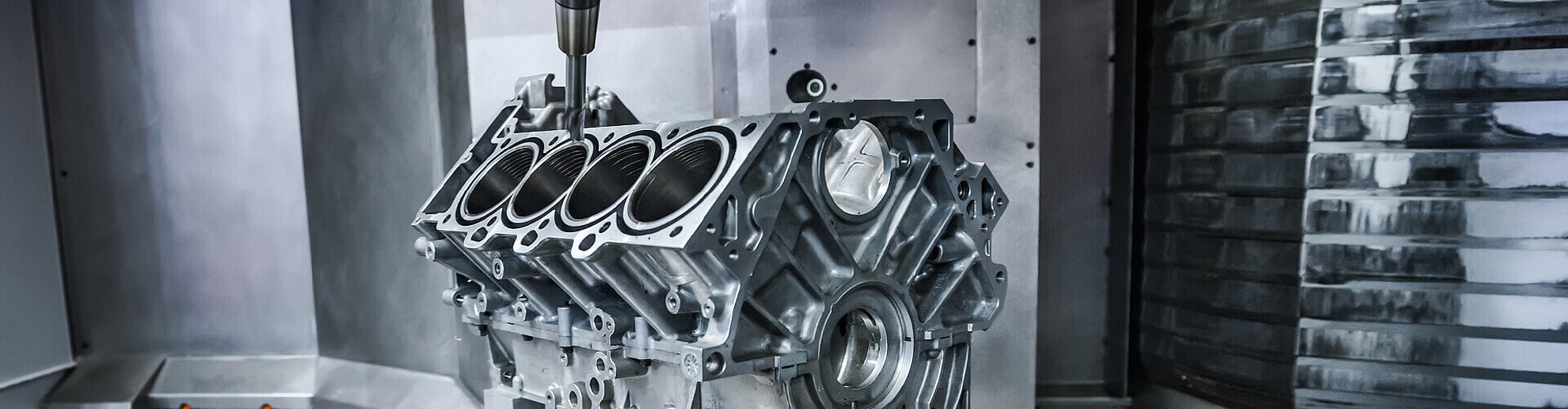

Cylinder housings are cast in blocks and find their use in the most diverse fields, but mainly in the engine technology. They are indispensable in vehicles, construction and industrial machinery and in the energy technology. Furthermore, they are necessary in wind power plants, as well as in the rail and drive technology. These diverse application areas require easy adjustment to the size and the respective application purpose. The Silbitz Group manufactures all cylinder housings in a particularly high quality, according to the customers’ requirements. The cylinder housings can exactly be integrated into already existing plants or can be constructed for completely new plants.

The motor technology components and customer expectations

Cylinder housings are cast as a block and are used in a wide variety of industries, but mainly in engine technology. Cylinder housings are indispensable in vehicles, construction machinery, industrial machinery and energy technology. They are also needed in wind turbines and in railroad and drive technology.

These diverse areas of application require adaptation to the size and the respective intended use. At the Silbitz Group, all cylinder housings are manufactured to the customer's specifications in a particularly high quality. The cylinder housings can be precisely integrated into existing systems or manufactured for new systems to be constructed.

Exact integration into already existing plants

Cylinder housings have to be constructed with a perfect and robust fit. After the integration into the machine or plant, very high forces are acting on them, depending on the mode of operation. The material has to withstand these forces. For this reason, cylinder housings are mostly constructed of a cast material. Very robust metals, which are not only weather-resistant, but also withstand a permanent contact with water and other liquids, are used. Neither can it break under the impact of very high forces. The shape of cylinder housings are exactly adjusted to the requirements. The form can either correspond exactly to the form of a classic cylinder or can deviate from this. It depends on the application area. There are many cylinder housings, of which the form doesn’t correspond to the one of a classic cylinder and which must be adapted accordingly.

Cylinder housings meet the highest quality standards

A high quality is the most important criteria when it comes to the construction of a cylinder housing. The parts are integrated into engines and electric drives, where a reliable function is most important. A machine failure because of a defective cylinder must be avoided from the outset, as unplanned downtimes are expensive. Furthermore, a failure of the cylinder can cause damages to other components, which can lead to expensive repairs. That’s the reason why cylinder housings have to be constructed of cast materials that are unbreakable and extremely resilient. Similarly, it is necessary to adapt the material to the construction.

Flexible in terms of form and design

Depending on the application area, cylinder housings can differ in form and size. It can be necessary to provide them with openings for the transport, in order to allow liquids, such as oil, fuel or water, to drain completely. Electrical use requires a continuous supply of electricity into the inner plant. Therefore, cylinder housings are custom made, according to the individual requirements. The construction of a cylinder housing starts with an exact drawing. The second step follows by a very precise production process, which guarantees a high processing quality and an absolute precision fit. Attachment parts can be seamlessly connected to the cylinder housing, so that a replacement or a subsequent integration is easily possible.

From quality control to delivery – the Silbitz Group is your contact for this sector.